The entire process of converting unprocessed nonwoven fabric into completed, packaged wet wipes ready for consumer use is automated by a wet wipes machine. The process typically consists of six significant steps; however, designs might differ.

Jumbo rolls of nonwoven material are put into the machine to start the fabric unwinding process. The cloth feeds easily without wrinkling or straining thanks to a tension-control mechanism. After that, the fabric is sent to the folding and cutting unit, where it is cut into uniform sheets and moulded into the required format (Z-fold, C-fold, or W-fold).

The lotion application step comes next, in which a dosing mechanism evenly distributes a liquid, such as baby lotion, disinfectant, or cleaning solution, onto the cloth by pumping or spraying it onto the fabric. To guarantee that the wipes remain wet without spilling, precise management is essential.

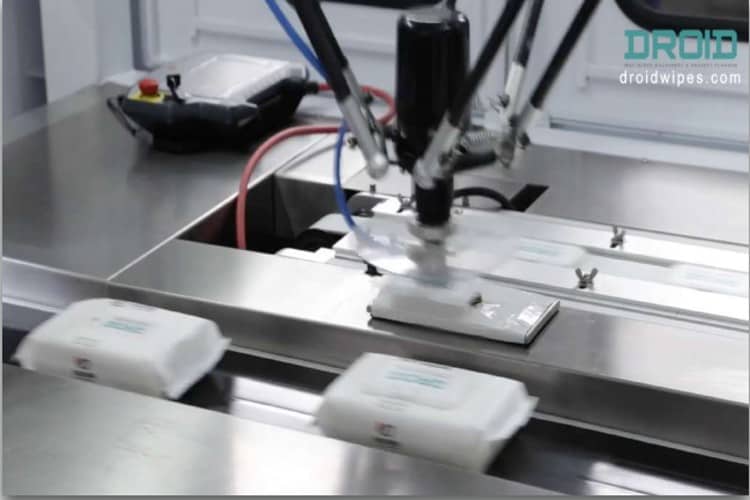

The sheets are then stacked and tallied into predetermined packs, such as 10, 40, or 80 wipes. After being moved inside the packing equipment, the stacks are wrapped in film, sealed using heat or ultrasonic technology, and often die-cut for resealable labels or easy-open features.

Lastly, the finished packs are sent to secondary packing tools for shipment and boxing, including palletizers or case packers.

To identify miscounts, misfolds, or empty packs, contemporary wet wipes incorporate quality control sensors. Additionally, they are designed to be quickly switched out, allowing producers to switch between various wipe sizes or packaging forms easily. The widespread need for wipes for personal hygiene, cleaning, and infant care can be met by high-speed versions, which can produce 800–3,500 wipes per minute.

A wet wipes machine essentially uses automation, hygienic compliance, and precision engineering to produce high-quality wipes reliably and in large quantities.