4 Packs/Bag

4 Packs/Bag

3 Packs/Bag

Applications

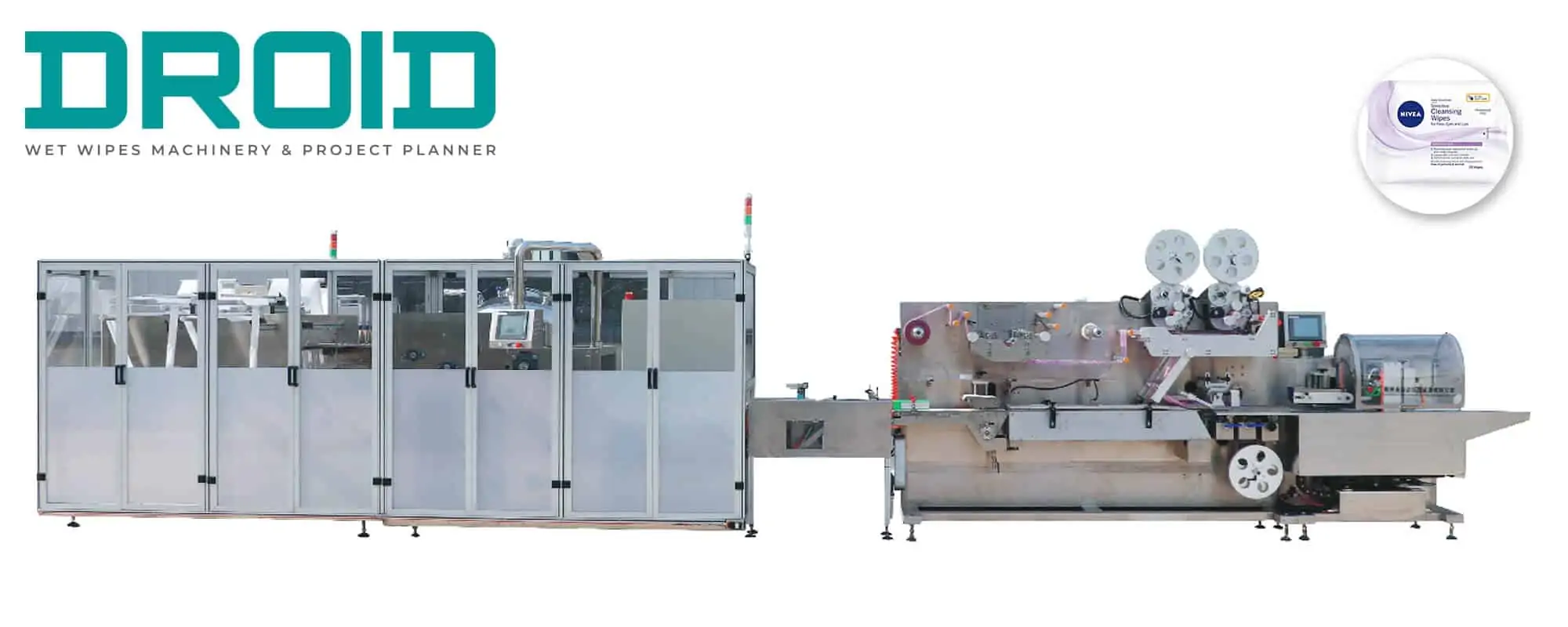

DH-MP80 is designed to stack and multi-pack pre-packed wet wipes (2~6 packs at a time) into premade PE bags.

DH-MP80 Multipack Wet Wipes Bagging Machine Features

DH-MPP80 is designed to stack and multi-pack pre-packed wet wipes (2~6 packs at a time) into premade PE bags.

It is also deemed as a technology breakthrough as the first automatic bagger for multipack wet wipes in China engineered to be economical viable to mainstream market.

Most Wet Wipes brands offer their consumers “Value Pack” with multipacks (often 2~6packs) of wet wipes packed in a portable PE bag. Traditionally, 98% of such package is done manually that requires at least 4 labors ineffectively working from end of the primary production line.

Faced with the pressuring challenge from labor shortage and higher-than-ever manufacturing costs against the backdrop of pandemic, automation is the sure way to go if one hopes to stay competitive in the market.

However, wet wipes manufacturers are left with very limited options for an automatic packaging machine for multipack wet wipes. The costs of an automatic solution available in current market is the major turnoff to many wet wipes converters as they fail to see a rosy ROI they expect.

That is why DH-MP80 automated multipack wet wipes packaging machine is born under relentless R&D efforts as an economical solution that features high performance & compact design to help small, medium or big sized wet wipes manufacturers cut manufacturing costs, increase productivity and maintain a competitive advantage.

DH-MP80 Bagging Machine for Multipack Wet Wipes Parameters

Dimensions and performance depending on options and product features. Different dimensions possible upon request.

| Model | DH-MP80 |

| Output product type | 2/3/4/5/6 Multipacks of Wet Wipes in a PE Bag |

| Capacity speed | inlet Speed: 40-80packs/min; Output Speed: 20-40 packages/min |

| Final Multi Package Dimensions (LxWxH) | (320-400) x(150-200)x110mm |

| Input Product Dimensions (LxWxH) | (150-220)x(80-120)x(40-80)mm |

| Packs in a bag | 2/3/4/5/6 in a bag (Input product height 40-80mm/pack) |

| Dual bag storage bins | √ |

| Non-stop pre-made bags change-over | √ |

| Automated Fin Trimming unit | √ |

| Machine materials in contact with products | made of SUS304 Stainless steel |

| Voltage | AC 380V, 50/60Hz, 3 Phase 5 wires |

| Packing size | (100-350)x(80-110)x(5-120)mm (LXWXH) |

| Power | 13kw |

| Air consumption | 200L/min |

| Applicable Material | Pre-made Bags; PET/PE BOPPPET/AL/PE and other suitable heat-sealable material |

| Machine size | 3700×3600×1900 (mm) |

| Machine weight | 5000kg |

| Optional add-ons | Coding machine/ Metal detector& Checkweigher/Vision & Reject System |

What is the DH-MP80 Multipack Wet Wipes Bagging Machine?

The DH-MP80 is an automated wet wipes machine that is specifically engineered to efficiently load multipack wet wipes into flexible packaging.

What types of wet wipes can it package?

Baby wipes, disinfection wipes, makeup removal wipes, and home cleaning wipes may all be packaged in it.

What bag sizes does it support?

A variety of bag sizes are supported by the machine, which may be adjusted to suit particular requirements.

Which packaging materials are compatible?

PE, laminated films, and other flexible packaging materials are supported.

Is the DH-MP80 fully automatic?

Yes, it minimizes human effort by having automated feeding, bagging, sealing, and cutting functions.

Does it have a user-friendly control system?

Yes, it has a sophisticated HMI touchscreen for real-time monitoring and simple operation.

Can the DH-MP80 integrate with other production lines?

Yes, it easily integrates with wet wipes manufacturing lines for complete automation.

Can it handle different stacking configurations?

Yes, the number of stacks per bag may be changed.

How easy is it to install the DH-MP80?

With comprehensive instructions and remote technical help, it is intended to be simple to install.

What maintenance does the machine require?

Cleaning sealing components, lubricating moving parts, and verifying the accuracy of sensors are all examples of routine maintenance.

How long does the machine last?

The DH-MP80 may last 8 to 10 years with the right care.

Are spare parts readily available?

Yes, DROID offers replacement components and post-purchase assistance to guarantee seamless functioning.

Can the DH-MP80 be customized for specific packaging needs?

Yes, DROID provides for customization in terms of automation levels, sealing choices, and bag size.

What should I do if the machine stops unexpectedly?

Look for problems with the power supply, packing film jams, or misaligned sensors. Error diagnostics are available in real-time via the HMI touchscreen.

Is training available for operators?

Yes, DROID offers thorough setup, operation, and maintenance training.