UT-P300

CoRobot Palletizer for Wet Wipes Production

As Easy to Operate as You Need

Your Operator is Guaranteed to Operate the Robot Within 1 hour.

Switch Between Different Formulas with One-click

Operate with Ease:

- Less than 1 hour, operator can master the operation of Robot

- Create a new formula: Enter the box specifications to generate a Tetris-style selection layout for single-layer placement.

- Different layer arrangements can be set, and operations can be managed in the background.

- Switch between different formulas with one-click.

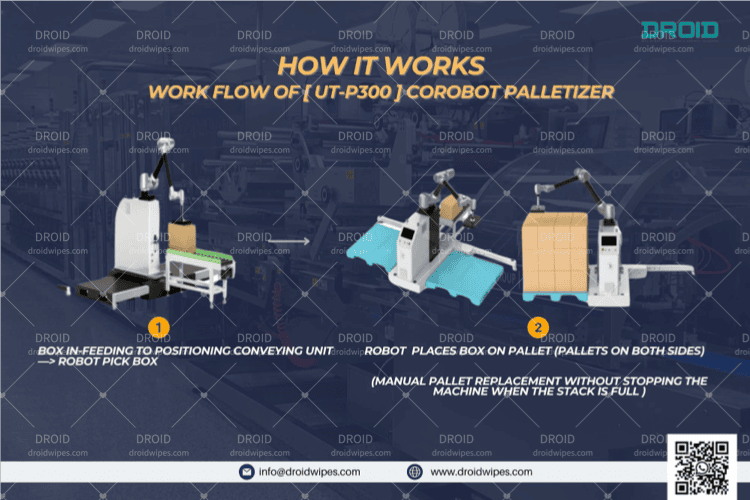

Robot shutdown and startup:

- Robot can continue to operate after non-destructive alarms, manual pauses, etc., without returning to the origin.

Pallet replacement:

- When the stack is full, the robot will automatically remind you to change it. When the pallet replacement is completed, the reminder will end; when the pallet is not full, press the button to replace the pallet.

- Operate the replacement button, and the sensor automatically detects whether the pallet is placed in place.

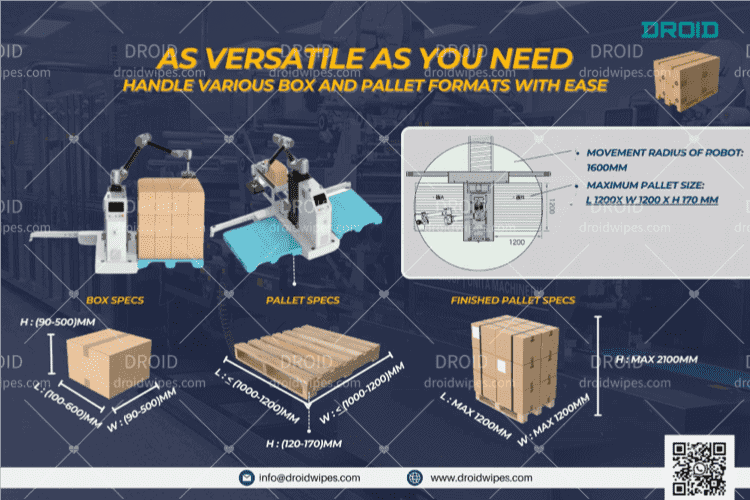

As Versatile As You Want

UT-P300 Robotic palletizer for wet wipes production is designed to handle various box and pallet formats with ease

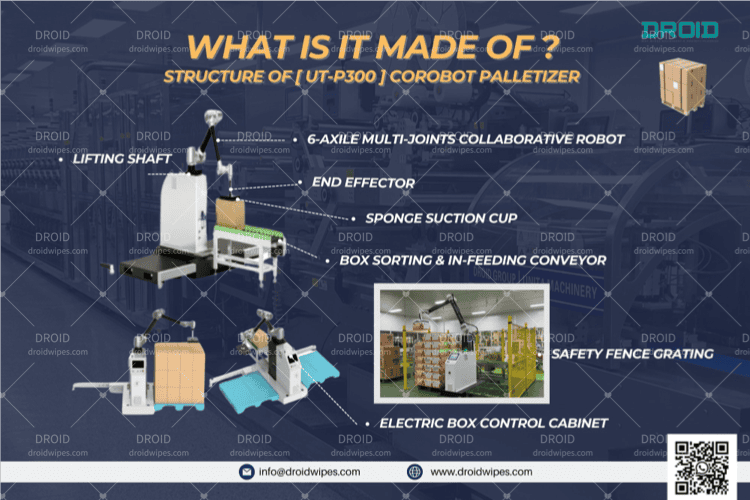

Technical Data of UT-P300 CoRobot Palletizer

| Model | UT-P300 |

|---|---|

| Robot Type | 6-Axile Multi-Joints Collaborative Robot |

| Capacity | 25-40 Boxes/min (Related to box size) Or Max Stable 10-12 Beats/min (The actual production speed depends on the actual production load. The speed per minute is directly related to the weight of box. The greater the load, the corresponding production speed will also decrease, but more gripping can meet the production speed of 25~40 boxes per minute) Speed Example per Grabbing: |

| No. of boxes per single grabbing | 1~5 boxes (adjustable), and the optimal grabbing amount can be automatically calculated according to the arrangement |

| Robot Load | ≤25KG (including clamps weight) Single box weight should be less than 25KG (Note: The standard model has a movement radius of 1600MM, which can meet the maximum load ≤25KG/ ) |

| Stacking Height | ≤2100mm (Including pallet height) |

| Pallet Dimensions | Maximum: L(1,000-1200)mmxW(1,000-1200)mmxH (120-170) mm (Compatible with plastic and wood pallet) |

| Power | AC220V 50/60Hz | 3-5kw |

| Air Consumption | 0.4~0.8MPA ; 2000L/Min |

| Machine size | 1,050*1,716*2,300mm ( LxWxH ) |

| Machine weight | 350kg |

| Box Dimensions | L (100-600) mm* W (90-500)mm* H (90-500)mm |

| Stacking Way | According to customer requirement |

| Lifting Shaft Distance | 500mm |

| Repeat positioning precision | +-0.03mm |

| Radius of action | 1600mm |

| Safety Design | • Emergency Stop Function • Safety Door Signal • Safety Fence Grating • Anti-collision detection • Users can Preset anti-collision trigger conditions. |

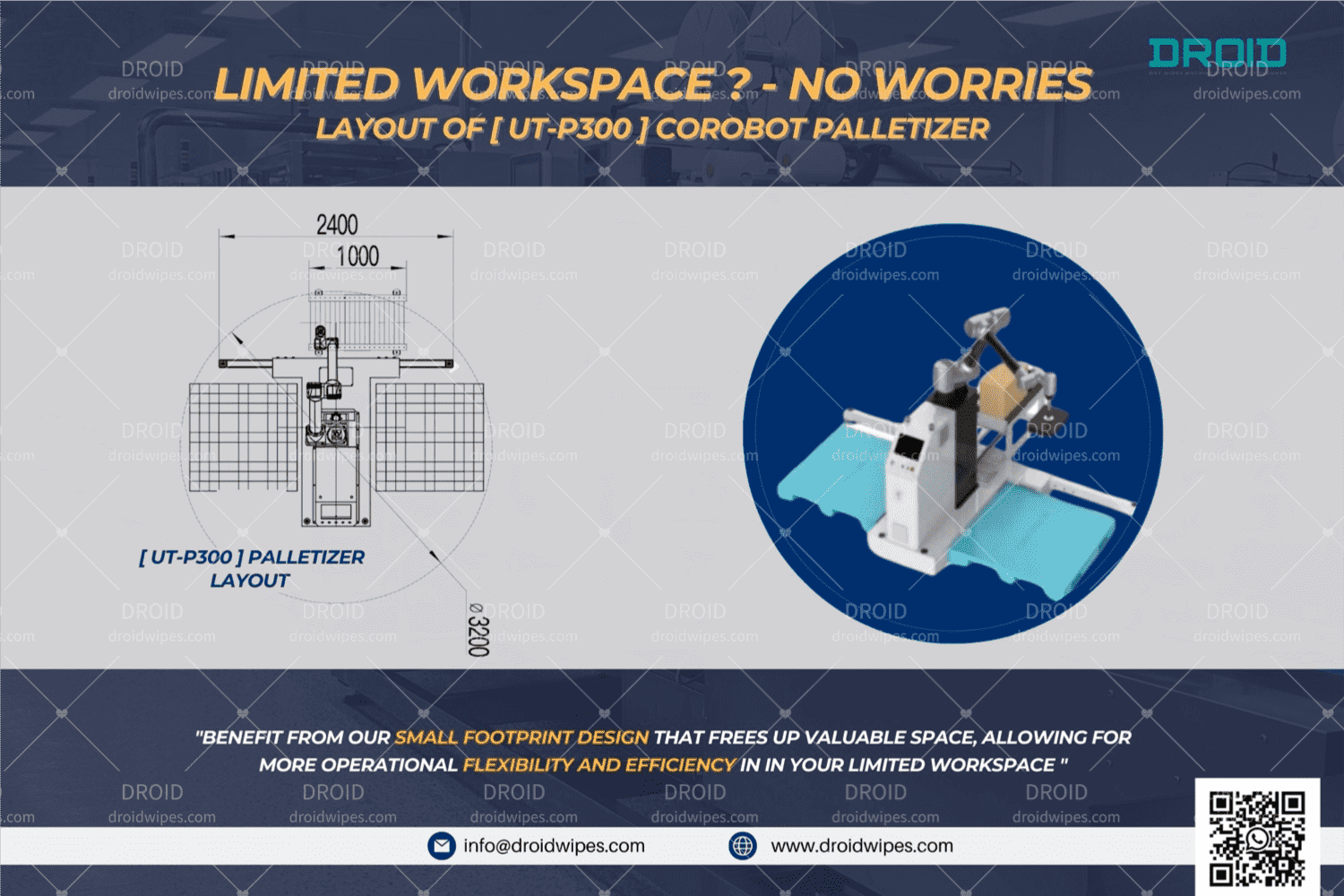

Machine Layout of UT-P300 CoRobot Palletizer

Maximize your workspace efficiency with compact design of our CoRobot Palletizer!

This space-saving solution allows for optimal use of your production area, enabling more equipment or operational activities within the same footprint.

Enhance your facility’s productivity without expanding your physical space—ideal for businesses looking to grow within limited confines.

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

Worry About After Sales Technical Support?

Guaranteed Technical Support and Training:

“We’ve Got Your Back, Every Step of the Way!

Peace of Mind in Every Wipe, Backed by Warranty.

Are You Looking for A Compete Wet Wipes Production Line?

You Might Be Interested

Wet Wipes Converting & Packaging Machines