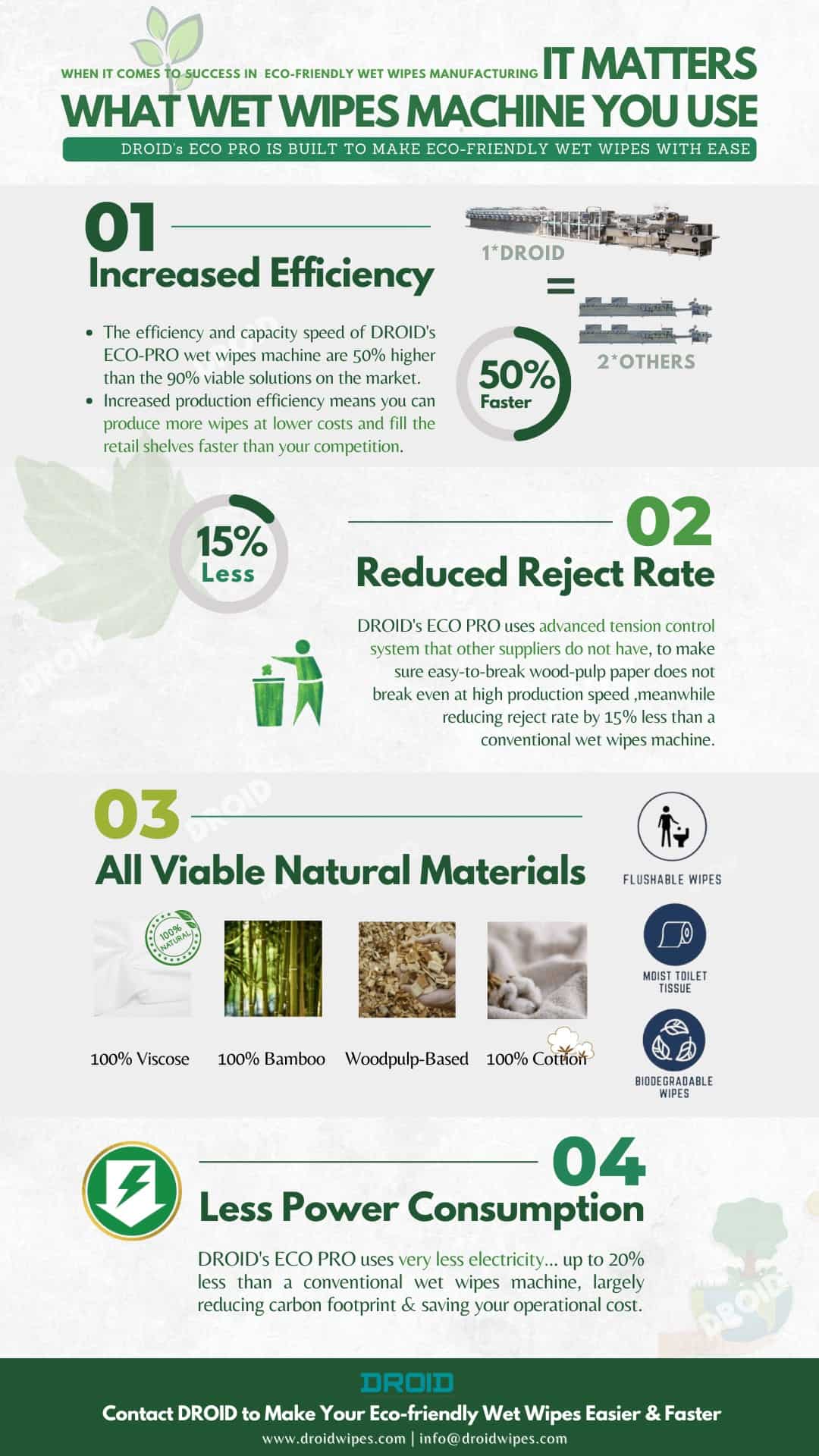

The flexibility and accuracy required to process 100% biodegradable textiles without compromising speed, effectiveness, or product quality are built into DROID wet wipes machines. To minimise the risk of stretching or tearing, our sophisticated material feeding systems utilise adjustable tension control to carefully guide delicate natural fibres, such as bamboo, wood pulp, and cotton blends, through each stage of manufacturing.

Our machines’ precision cutting equipment is designed for precise, clean cuts, guaranteeing that the edges of biodegradable wipes stay intact and presentable. Even when switching between various environmentally friendly substrates, our machines’ programmed folding options ensure consistent proportions and seamless stacking by adapting to variable material thicknesses.

To preserve strong, dependable seals while protecting heat-sensitive, biodegradable textiles, DROID utilises low-heat and ultrasonic sealing technology. Our precise and reliable liquid dosing methods prevent oversaturation, which can deteriorate the fabric or compromise the quality of the wipes.

Furthermore, producers may swiftly transition between conventional and biodegradable materials due to our machines’ support for modular modifications. Without having to make significant equipment adjustments, this flexibility enables organisations to satisfy both present production demands and future market trends.

With these features, DROID ensures that producing environmentally friendly wet wipes is not only feasible but also profitable, helping manufacturers achieve sustainability targets, comply with global laws, and capture premium market niches.