The Long-Term Benefits of High-Quality Wet Wipes Machines

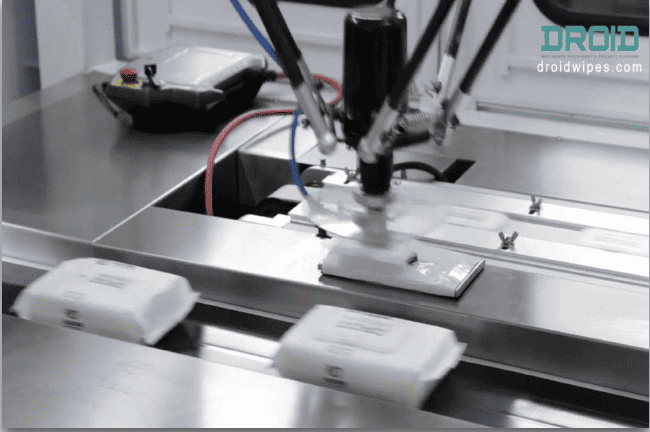

Purchasing high-quality wet wipe machines is not only an option in today’s competitive personal care and hygiene industry, but it is also a strategic necessity. DROID, as a seasoned provider of wet wipes machinery with over 16 years of experience, we are aware of the direct impact that accurate, dependable, and effective equipment has on product quality, operational efficiency, and brand reputation. Advanced wet wipe machines offer long-term benefits that extend far beyond short-term productivity gains, as wet wipe manufacturers worldwide are discovering. The benefits are obvious, ranging from lower maintenance costs and more consistent production to increased customer confidence and adherence to stringent hygiene regulations. This article explains why investing in high-quality wet wipe machines is a wise long-term investment and how it can help your company prepare for the future in a rapidly changing market.