Wet wipes that are individually packaged, usually with one or two sheets per pouch, are produced using a single-sachet wet wipe machine. These devices are extensively used in sectors such as hospitality, aviation, healthcare, and cosmetics, where there is a strong need for portable, clean wipes.

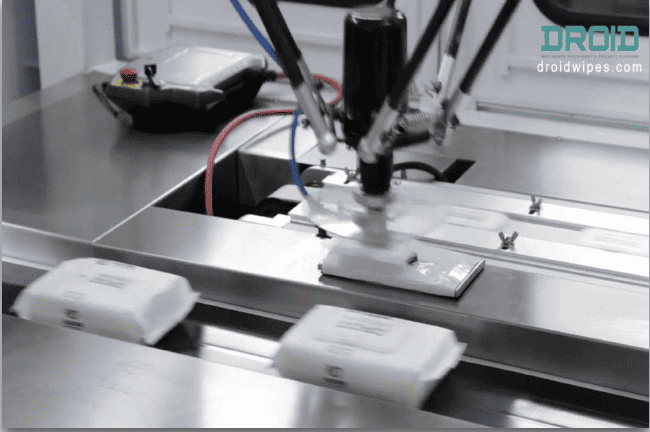

Nonwoven fabric is first fed into the machine, which then folds, cuts, and moistens each sheet with the preferred liquid formula, such as disinfectant, cleaning agent, or refreshing solution. To maintain moisture and guarantee product cleanliness, the machine next wraps the wipe within a foil sachet or protective film.

Because they are convenient to use while on the road, single-sachet wet wipes are a popular choice. They are distributed by airlines before meals, served to patrons at restaurants, included in hotel amenity packs, and used as promotional handouts by corporations. Sanitising wipes that are individually packaged are crucial for preserving sterility in medical settings.

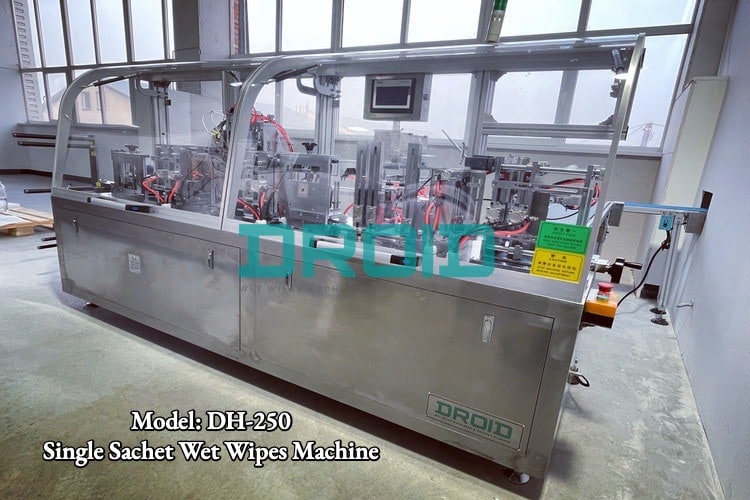

Compared to multipack lines, single sachet machines are usually faster and smaller from a manufacturing perspective. Additionally, they are adaptable, enabling quick switchovers to other liquid types or branding. Because of this, they may be used by both small and large companies that produce bespoke batches.

The cost of packaging materials per wipe is higher, even if the unit price of a single sachet is sometimes more than that of wipes in bulk packs. The premium positioning and branding potential these wipes provide should be weighed against this by manufacturers.

In summary, companies aiming to sell high-end, portable, and hygienic goods would be well advised to consider a single sachet wet wipes machine. It helps companies satisfy customer demands for convenience and cleanliness, wherever and at any time, by providing speed, flexibility, and a polished finish.