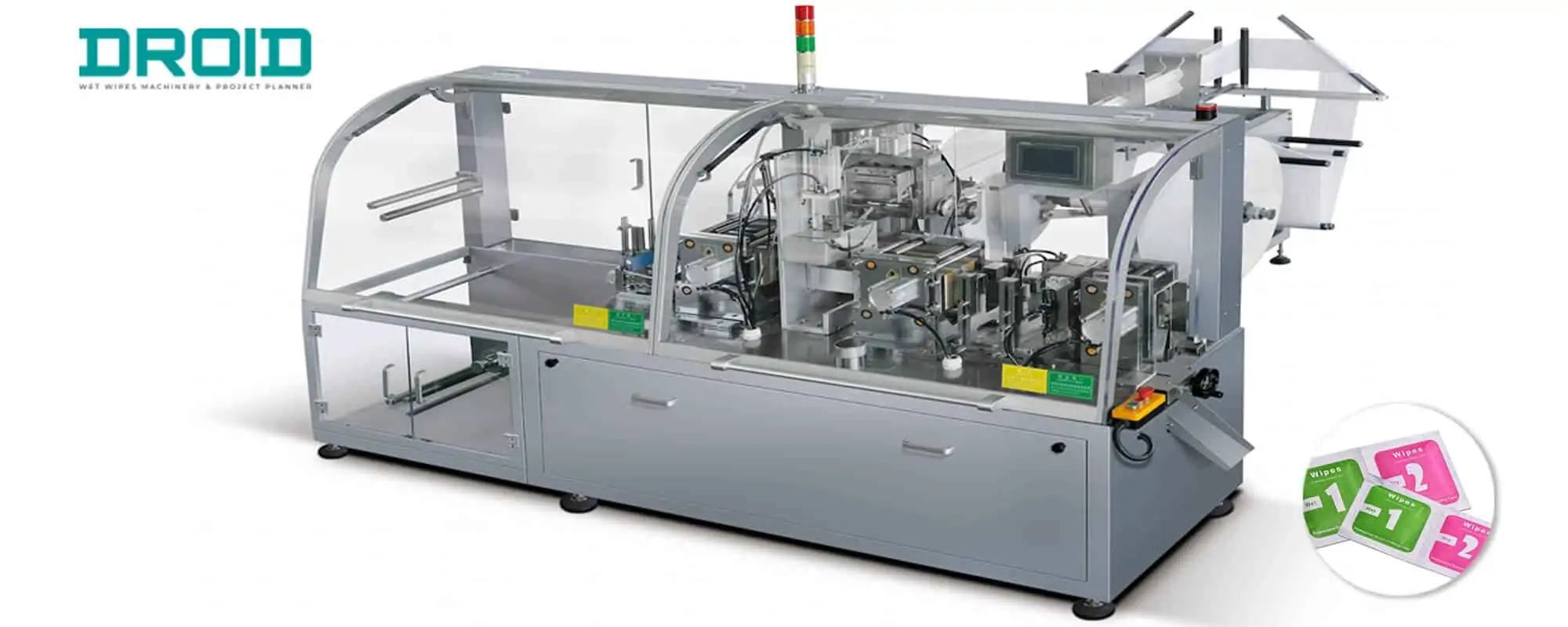

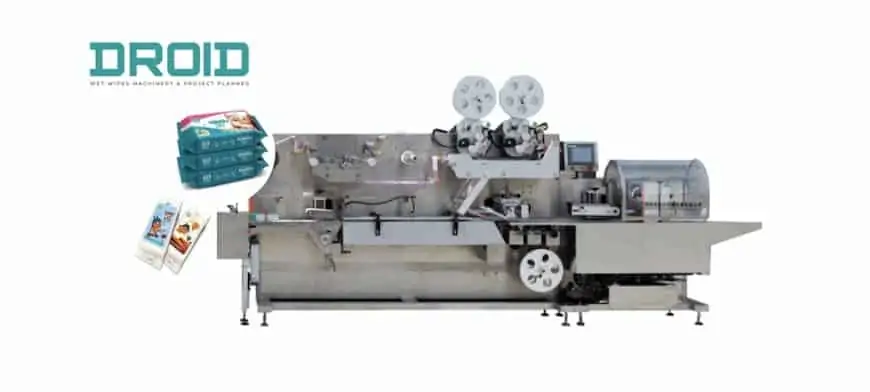

DH-250 Single Sachet Wet Wipes Machine

DH-250 Single Sachet Wet Wipes Machine Running Demo

PRODUCT DETAILS

Features

DH-250 single sachet wet wipes machine is specialized to make travel-sized wet tissue in single sachet or dual packs.

Its application is as wide as to include personal hygiene wipes, alcohol swabs/pads, disinfectant wipes, airline wipes, facial wet tissue, hand sanitizing wipes or makeup removal wipes.

- Full automated with no need for human interference throughout the production process

- Full Servo drive and PLC control system

- Tissue length and width size changed by servo system, no mechanical adjustment needed

- Compact structure to save working space

- All conveyor belts are food-grade, anti-bacterial and suitable for hygienic product transfer

- 304L Stainless steel is applied to the cover of machine and main spare parts in contact with liquid and fabric

- User-friendly HMI with touch screen

- Structure: raw material loading device, tension device, folding device, forming device, bottom sealing device, online wetting system, automatic counting device, code printing device, packing device for finished products.

Output Product:

Personal care wipes:

Alcohol Swabs/Pads

Airline Wipes

Antiseptic Swabs

Disinfecting Wipes

Hygiene Wipes

Hand Sanitizing Wet Wipes

Antibacterial Wipes

Refreshing Wet Wipes

Facial Cleaning Wet Tissue

Body Wet Towel

Feminine Wet Wipes

Makeup Removal Wet Wipe

Beauty wipes

Restaurant Wipes

Hotel Wipes

Glass Cleaning Wipes

Shoe polishing wipes

Lens cleaning wipes

Wipes for general purpose

Deodorizing Wipes

Machine Parameters

- Model: DH-250

- Output product type: Alcohol swab; refreshing wipes; Airline wipes

- Packaging form: 4-side-sealing; Single/ dual packs

- Full automatic: tissue converting machine + packaging machine (No Human Touch)

- Work flow: Auto material loading → Tissue folding→ Tissue slitting → online wetting →tissue delivery to packaging machine → data printing → 4 side sealing & bag forming →finished product output

- Capacity: 60-120packs/min

- Control system:PLC + Full servo driven system

- Suitable material: [35-80gsm] spun-lace nonwoven; wet strength paper

- Packing material: CPP,PE,BOPP Folding ways: Max 4 times of vertical folding | Max 10 times of horizontal folding

- Packing material: CPP,PE,BOPP

- Open tissue size:(30-200)x(30-250) mm

- Packing size: (40-170)X (40-110)mm

- Wetting system: Quantitative range 0-15ml

- Power: Single phase; AC220V 50/60Hz | 3 kw

- Operation interface: touch screen

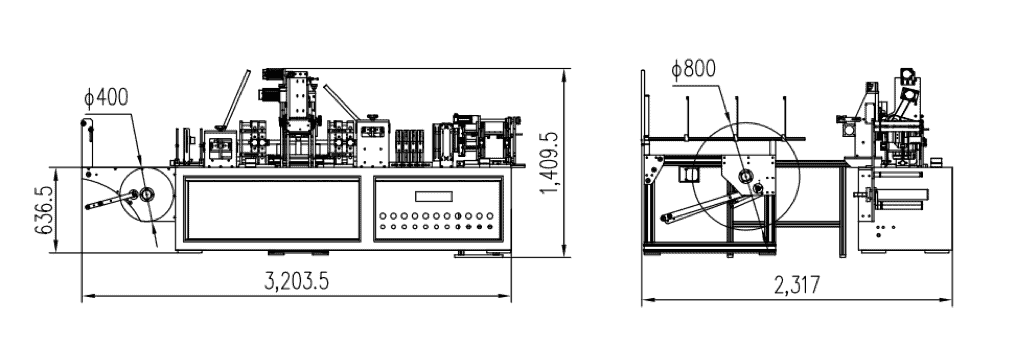

- Machine size: 3000×2800×1800 mm(L*W*H)

- Machine weight: 1100kg

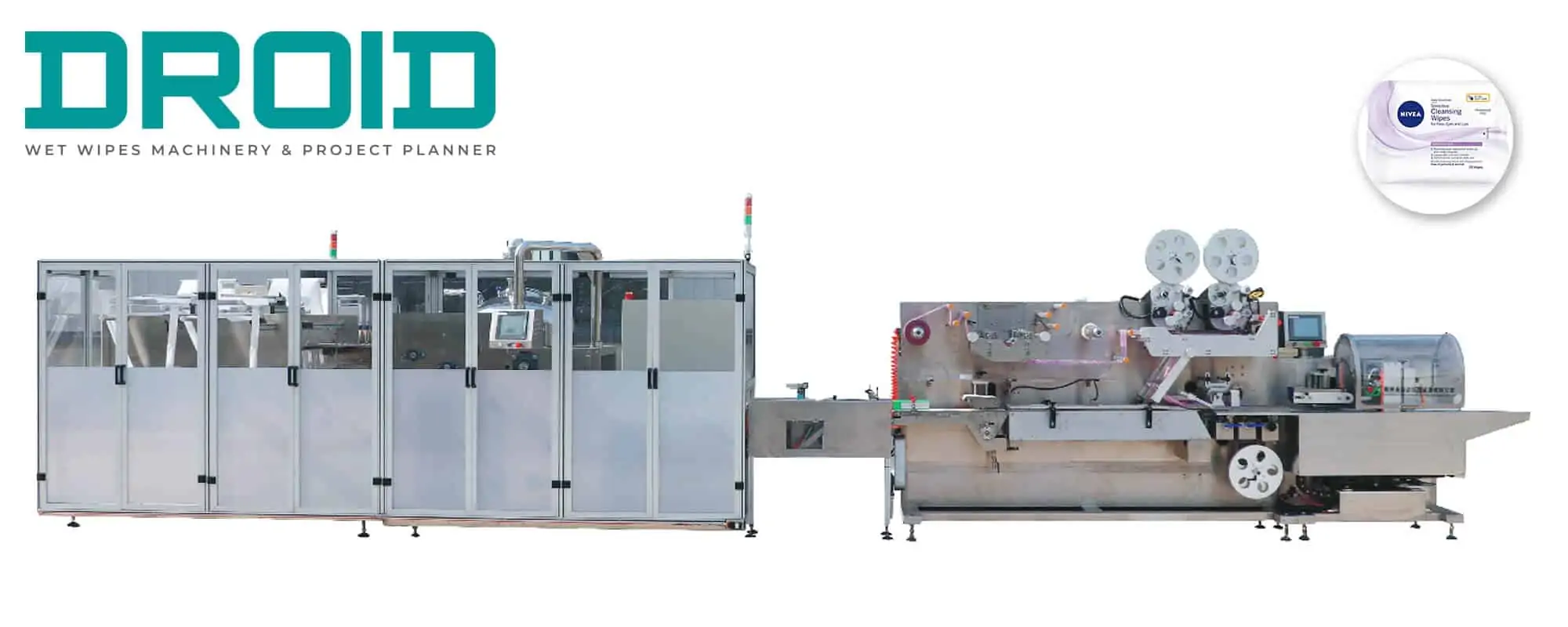

Machine Layout

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What types of wet wipes can the DH-250 produce?

The DH-250 is engineered to manufacture a diverse range of single-use and dual-pack wet wipes, including:

-

Alcohol swabs and pads

-

Disinfectant and antiseptic wipes

-

Hand sanitizing and antibacterial wipes

-

Facial cleansing and makeup removal wipes

-

Airline and hospitality wipes

-

Feminine hygiene and body wipes

-

Glass, lens, and shoe cleaning wipes

-

Deodorizing and general-purpose wipes

What is the production capacity of the DH-250?

The DH-250 functions at a speed of 60 to 120 packs per minute, depending on the product specifications and materials used.

Which materials are compatible with the DH-250?

This DH-250 machine is compatible with:

-

Nonwoven fabrics (35–80 gsm spun-lace)

-

Wet-strength paper

-

Packaging films such as CPP, PE, and BOPP

What are the dimensions of the wipes and packaging?

-

Open tissue size: 30–200 mm (L) × 30–250 mm (W)

-

Packaging size: 40–170 mm (L) × 40–110 mm (W)

-

Folding options: Up to 4 vertical folds and 10 horizontal folds

Is the DH-250 fully automated?

Yes, the DH-250 is a fully automated system that includes:

-

Raw material loading

-

Tissue folding and slitting

-

Online wetting

-

Packaging with four-side sealing

-

Data printing and automatic counting

This automation minimizes human intervention and upholds high hygiene standards.

What control systems are integrated into the DH-250?

The DH-250 machine features a full servo drive and PLC control system, enabling precise adjustments to tissue length and width without requiring mechanical modifications.

What is the power requirement for the DH-250?

The DH-250 operates using a single-phase AC220V power supply at 50/60Hz, with a power consumption of 3 kW.

What are the DH-250 machine’s dimensions and weight?

-

Dimensions: 3000 mm (L) × 2800 mm (W) × 1800 mm (H)

-

Weight: Approximately 1100 kg

Does the DH-250 comply with hygiene standards?

Absolutely. The DH-250 machine features:

-

Food-grade, anti-bacterial conveyor belts

-

304L stainless steel components in contact with liquids and fabrics

These features ensure compliance with stringent hygiene requirements.

Is training and installation support provided?

DROID provides thorough installation and commissioning services. Up to two technicians can be sent to your facility within seven days to complete the installation, commissioning, and staff training, excluding travel time.