PRODUCT DETAILS

PRODUCT SPECIFICATIONS

- Model: DH-12N

- Output product type: 30-120 pulls/pack

- Loading station: 2 stations/ 2 Jumbo rolls

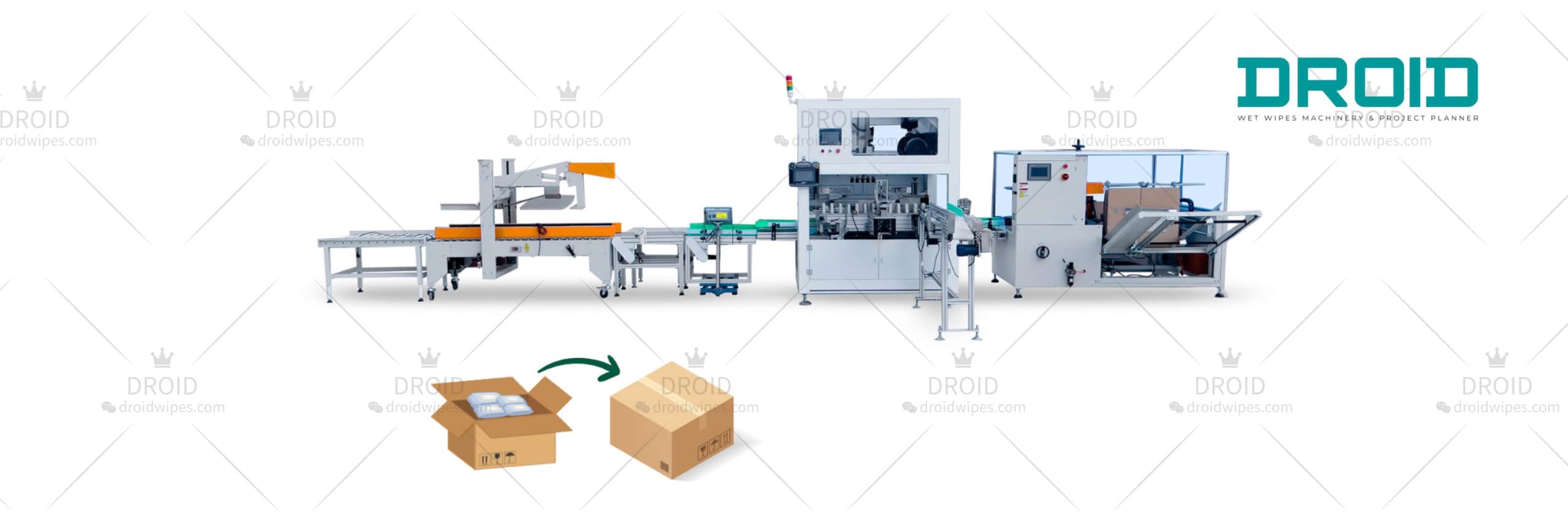

- Full automatic: 12 (10) lanes tissue converting machine + one flow pack packaging machine (No Human Touch)

- Work flow: Auto material loading → tissue slitting → Tissue folding→ online wetting → tissue cutting →stacking & counting →auto tissue delivery to packaging machine → punching →labeling →sealing →finished product output

- Capacity: Converting speed: 2800-3500pcs/min |

- Packaging speed: 30-40 packs/min (Subject to material types)

- Control system:PLC + Full servo driven system ■

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size:(70-170)x(160-220) mm

- Folded tissue size:(70-170)x(80-110) mm

- Packing size:(150-300)x(50-120)x(10-100)mm

- Folding ways: “Z” non-pop up/ ”N” fold

- Wetting system: online-wetting

- Power: AC380V 50/60Hz | 11.5 kw

- Operation interface: Swing arm touch screen

- Machine size: 9600×2600×1950 mm(L*W*H)

- Machine weight: 4500kg

PRODUCT DIMENSION

VIDEO

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What is the DH-12N wet wipes production line?

The DH-12N is a fully automatic wet wipes production system that produces packs containing 30 to 120 wipes. It integrates tissue converting and flow pack packaging into a seamless, no-human-touch process, ensuring high standards of hygiene and efficiency.

What is the production capacity of the DH-12N?

-

Converting speed: 2,800–3,500 wipes per minute

-

Packaging speed: 30–40 packs per minute (depending on material type)

Which materials are compatible with the DH-12N?

The DH-12N machine is suitable for:

-

Spun-lace nonwoven fabrics (35–80 gsm)

-

Biodegradable materials

What folding methods does the DH-12N machine support?

The DH-12N supports:

-

“Z” fold (non-pop-up)

-

“N” fold

What are the dimensions of the wipes and packaging?

-

Open tissue size: 70–170 mm (width) × 160–220 mm (length)

-

Folded tissue size: 70–170 mm (width) × 80–110 mm (length)

-

Pack size: 150–300 mm (length) × 50–120 mm (width) × 10–100 mm (height)

Can the DH-12N handle eco-friendly materials?

The DH-12N can process biodegradable materials, making it suitable for environmentally friendly wet wipes.

What is the workflow of the DH-12N production line?

The automated workflow includes:

-

Auto material loading

-

Tissue slitting

-

Tissue folding

-

Online wetting

-

Tissue cutting

-

Stacking & counting

-

Auto tissue delivery to packaging machine

-

Punching

-

Labeling

-

Sealing

-

Finished product output

What control systems are integrated into the DH-12N?

The DH-12N machine includes a PLC (Programmable Logic Controller) and a fully servo-driven system, which ensures precise control and high-speed operation.

What are the power requirements for the DH-12N?

-

Power supply: AC 380V, 50/60Hz

-

Power consumption: 11.5 kW

What are the dimensions and weight of the DH-12N machine?

-

Machine size: 9,600 mm (length) × 2,600 mm (width) × 1,950 mm (height)

-

Machine weight: 4,500 kg

Is the wetting system adjustable?

Yes, the online wetting system allows for adjustable liquid dosing, ensuring an even moisture distribution across all wipes.

Can the DH-12N be customized for specific requirements?

Customization options are available to accommodate specific production needs, including adjustments to folding styles, packaging sizes, and integration with additional equipment.

What maintenance is required for the DH-12N?

Regular maintenance includes:

-

Blade inspections and replacements

-

Sensor and servo calibrations

-

Lubrication of moving parts

-

Cleaning of filters and nozzles in the wetting system

What support and training does DROID offer?

DROID provides:

-

On-site installation

-

Operator training

-

Remote technical support

-

Warranty coverage and spare parts availability