Reliability is crucial for a wet wipes making machine since it’s a long-term investment. Frequent malfunctions, erratic performance, or expensive downtime are the last things you want to experience. Selecting a machine—and a manufacturer—with a track record of reliability and performance is crucial for this reason.

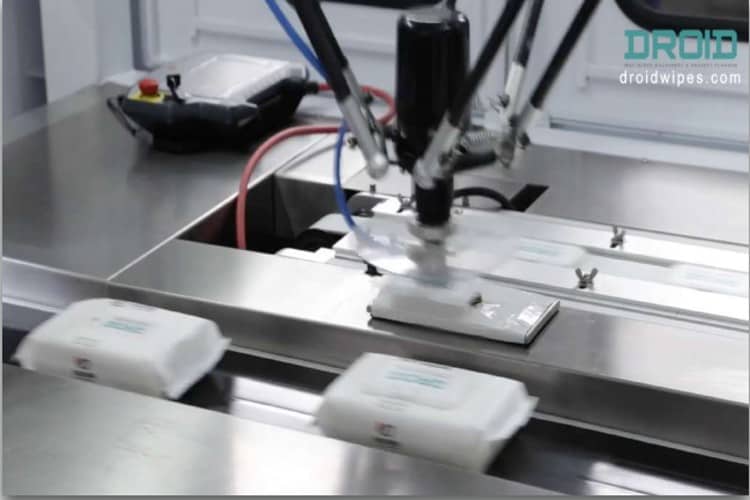

Examine the brand’s reputation first. Does the manufacturer have a worldwide clientele, documented case studies, or years of experience? For example, businesses like DROID are renowned for manufacturing machines that run reliably and continually in factories all over the globe.

Next, review user comments and feedback. Are consumers happy with the machine’s functionality, construction, and post-purchase assistance? Referrals from other manufacturers, industry forums, and independent evaluations may all provide insightful information about practical dependability.

Inquiring about certificates and standards that demonstrate the machine meets international safety and quality standards, such as CE, GMP, or ISO compliance, is also a good idea.

Although a dependable, well-regarded piece of equipment may not be the most affordable choice available, it will ultimately save you money by reducing replacement, maintenance, and downtime expenses. To put it simply, a reliable brand equates to a safer and more intelligent investment.