The speed and effectiveness of a wet wipes machine may be significantly influenced by the format and packaging material you choose. From film thickness to sealing qualities, every component affects how quickly and smoothly your manufacturing line operates.

Due to their reduced heat resistance, flexible packaging films—such as laminated PET or single-layer polyethylene—allow for quicker sealing. This raises cycle rates, hence enhancing throughput. On the other hand, if the movie is too thin or prone to stretching, it may lead to weak seals or feeding mistakes that call for regular corrections to slow down the process.

Conversely, multi-layer or environmentally friendly biodegradable films may require precise temperature control and extended dwell times to achieve effective sealing. Machines not suited for these materials may have lower efficiency, which would cause uneven sealing or maybe machine stoppages.

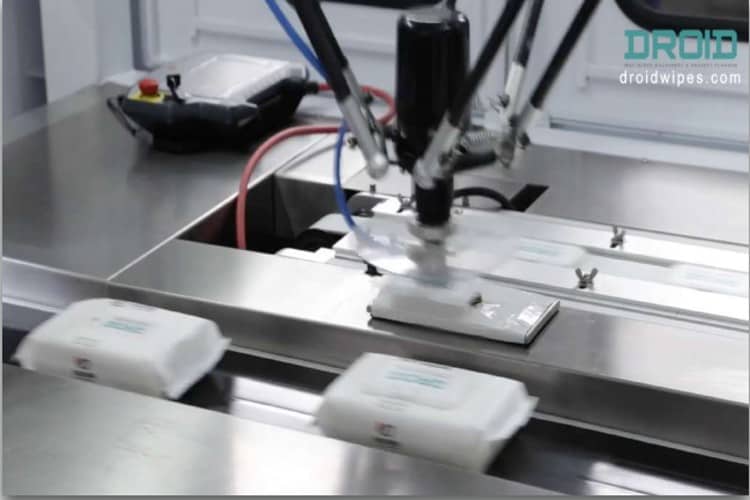

Packaging techniques also have importance. Flow wrap systems, for instance, typically provide better speed performance; canister and rigid box designs, on the other hand, function more slowly due to the additional stages of filling, dosing, and sealing. Every format affects the maximum output speed of the machine differently.

Furthermore, adding additional processing steps, such as resealable features, zippers, or labels, can enhance the product’s functionality. Only with high-performance servo-driven systems and perfect synchronizing can machines combine these characteristics without sacrificing speed.

Maintaining best performance depends on matching the capabilities of your machine with the selected packaging guidelines. Apart from supporting your current package style, a good wet wipes machine should be flexible enough to accommodate future material trends and format modifications.

Careful alignment of packing material and format with machine design helps producers prevent unnecessary slowdowns and maintain consistent production efficiency.