How Noisy Are Wet Tissue Machines During Operation?

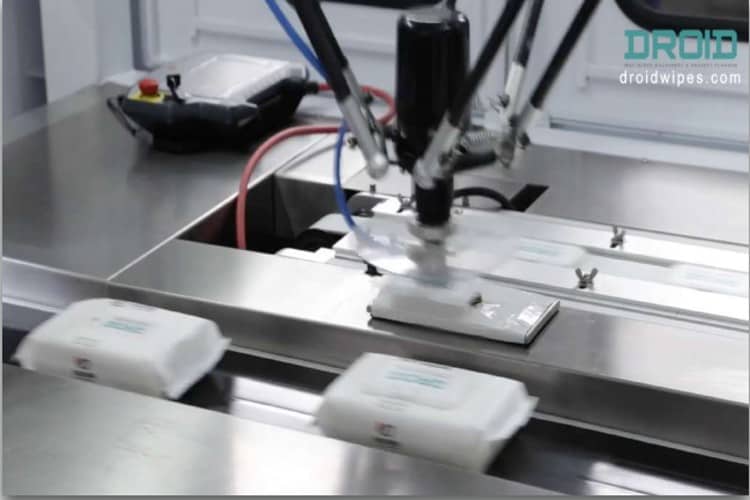

One question that often comes up when setting up a wet wipes manufacturing line is how loud these machines are. Wet wipes machines nowadays typically operate at a noise level of between 70 and 85 dB, which is comparable to the noise of a home vacuum or a busy street. Although not deafening, the level might affect comfort and productivity in a workshop and could even cause issues in settings where noise is a problem, such as laboratories or hospitals. Wet wipes manufacturers can make better equipment decisions and maintain a safer, healthier workplace by understanding where noise originates, comparing the performance of various machines, and identifying ways to reduce it.