Purchasing a robotic palletizer is a long-term choice that impacts customer happiness, labour savings, and efficiency. Wet wipe manufacturers should assess their equipment based on certain key factors to make the best decision.

1. Capacity of Throughput

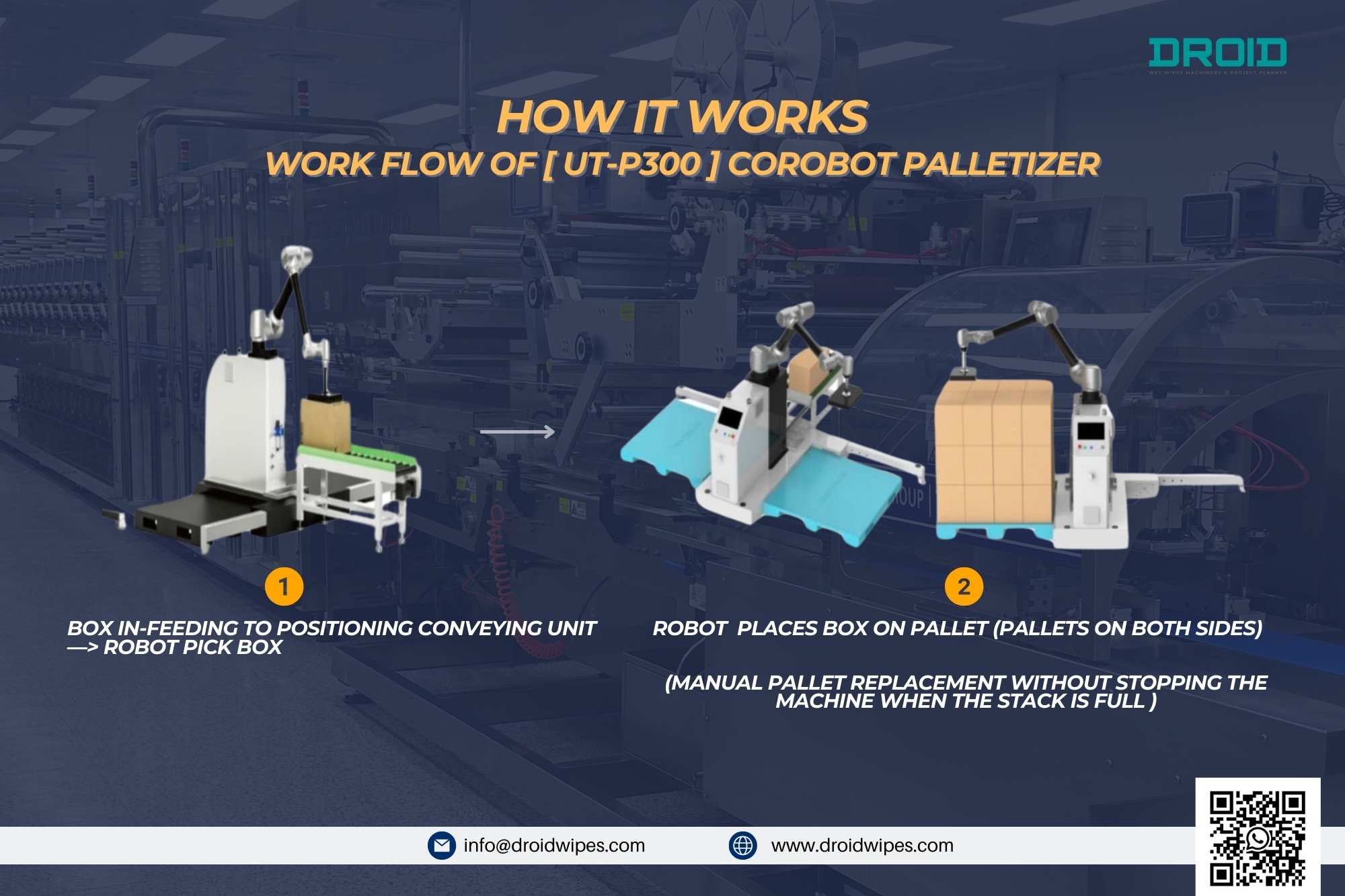

Verify that the palletizer can handle the 15–25 cases per minute that your case packer can produce. Both single-case and dual-case grippers’ cycle times should be checked.

2. Layout and Footprint

Assess the available floor space and review potential configurations (central, modular, or inline). A small palletizer should not interfere with traffic flow and fit into an area of 5 to 8 m².

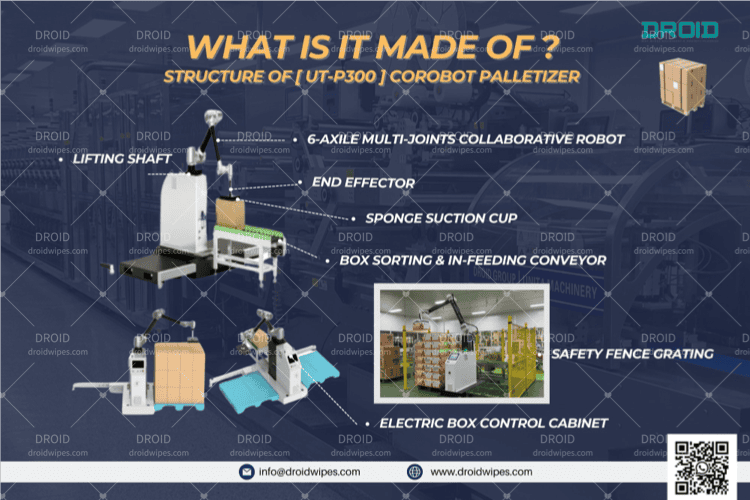

3. Technology Gripper

Selecting the appropriate end-of-arm tool (EOAT):

- Vacuum grippers for cartons that are lightweight.

- Clamp grippers for boxes that are unsteady or heavy.

If working with bundles or mixed formats, use custom solutions.

4. Flexibility of Pallet Patterns

Make sure there is little downtime when the robot switches between Euro and regular pallets, as well as between column, interlocked, or hybrid patterns.

5. Security and Adherence

Verify that the system complies with international safety standards, such as ISO 13849 and IEC/EN 60204-1, and incorporate collaborative or guarding features as necessary.

6. Readiness for Integration

Verify compatibility with wrapping machines, labelers, conveyors, and case packers. Integration enhances OEE and decreases manual touchpoints.

7. Repair and Replacement Components

Inquire about remote diagnostics, replacement part availability, and local technical help. To prevent expensive downtime, prompt service response is crucial.

8. The capacity to scale

Make development a priority. Select a solution that enables integration with factory MES systems, future updates, or more palletizing cells.

The ideal palletizer isn’t the one with the most specifications; instead, it’s the one that fits your needs in terms of space, product mix, throughput, and long-term growth.