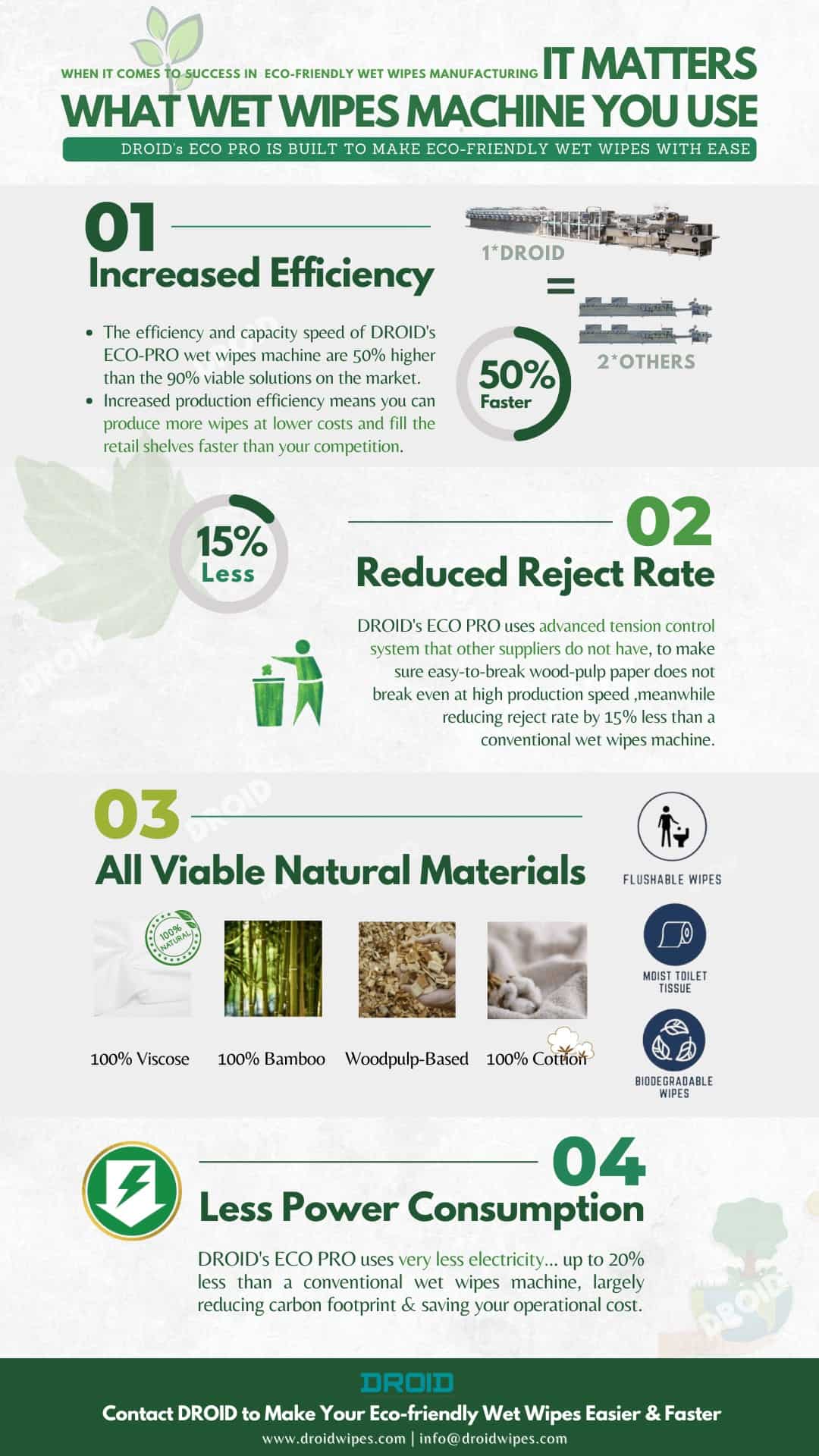

Wet wipes machines have an environmental impact, just like any other industrial equipment. Still, the extent of that impact varies depending on how the machine is made and how it is used. Conventional models often used non-recyclable materials, generated more scrap, and required more resources, which increased waste and energy consumption.

However, the construction of today’s sophisticated machinery takes into account sustainability. Many use trash collecting features to keep residual materials out of landfills, energy-efficient motors to conserve power, and precise cutting technologies to minimise fabric offcuts.

Compatibility of materials is another aspect. Manufacturers can choose more environmentally friendly products without compromising speed or quality by utilising machines that can process biodegradable textiles, recycled packaging films, and water-based or alcohol-free treatments.

Lastly, noise and pollution are factors. A cleaner, safer working environment is produced by modern wet wipes machines, which are usually low-noise and emission-free, meaning they don’t release smoke, oil mist, or hazardous vapours.

To put it briefly, wet wipe machines have sustainability concerns. Selecting the appropriate wet wipes machine—one built for effectiveness, minimal waste, and environmentally acceptable materials—can significantly reduce that impact and help producers meet international sustainability targets.