Although packaging is often the last stage in the wet wipes production process, it has a significant impact on cost and efficiency. Conventional machines are usually designed to process only one type of packaging, such as canisters, soft packs, or single sachets. When altering formats, this rigidity forces producers to either invest in numerous machines or endure lengthy changeover periods, both of which increase operational expenses.

More intelligent wet wipers are designed to be flexible. Due to its quick-change systems and modular design, operators can switch between package types in a matter of minutes, rather than hours. For instance, without requiring significant modifications or additional equipment, a manufacturing line can transition from producing multipacks for retail shelves to canisters for institutional purchasers.

Because sophisticated equipment can handle a wide range of products, this adaptability minimizes downtime, optimizes machine utilization, and reduces capital expenditure. Additionally, it enables producers to react swiftly to consumer requests by creating family packs, travel-sized sachets, or specialty wipes for medical and hospitality settings.

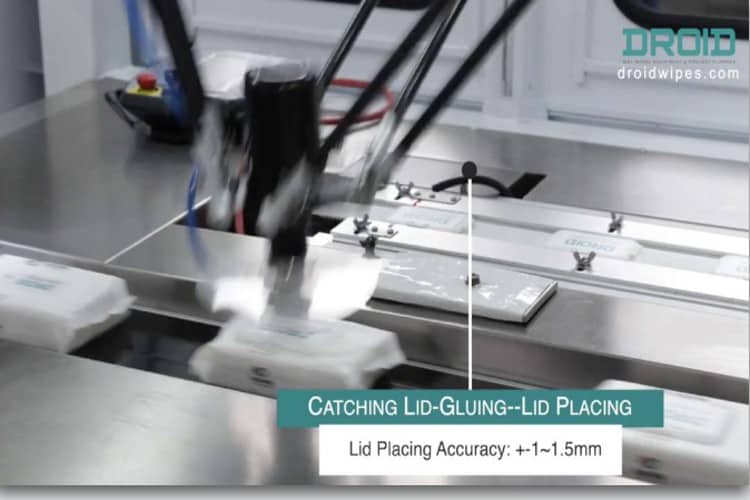

Modern machines also feature advanced packaging controls that enhance sealing accuracy and reduce film waste. In addition to saving money on packaging, this ensures a more standardized and polished end product, thereby improving the brand’s image.

Wet wipes manufacturers can increase production, reduce costs, and acquire the agility they need to remain competitive in a rapidly changing market by selecting equipment with flexible packaging capabilities.