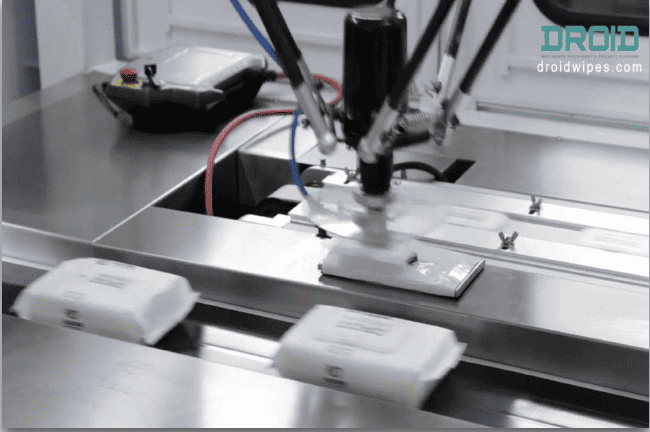

Every pack satisfies strict quality and consistency requirements when your wet wipe machine is calibrated correctly. Pay close attention to these crucial steps:

1. System for Dosing Solutions

Verify the liquid dosing pump to make sure the proper quantity of solution is applied to each wipe. Measure the output using a precise scale. Using the control panel, change the pump’s pressure or speed until it reaches your desired weight.

2. Calibration of Material Tension

To determine the nonwoven fabric’s tension, use a tension gauge. To maintain the fabric smooth and free of wrinkles, adjust the tension settings or the dancer’s arm. This guarantees even folding and prevents ripping.

3. Temperature of Ultrasonic Sealers

Use a thermometer to confirm the temperature of the ultrasonic sealer. Check it against your setpoint. To prevent weak or over-melted seals, adjust the ultrasonic generator or heater settings if they are set too high or too low.

4. Power and Pump Adjustment

Verify that all pumps are operating at consistent power and flow rates by inspecting them. If necessary, adjust the machine’s variable frequency drives (VFDs) and look for any variations in the power supply.

5. Calibration of Cut Position

Use a caliper or measuring ruler to determine the pack’s length. To ensure that every pack is consistently and neatly sliced, adjust the cutting time and blade position on the machine’s control panel.

These procedures will ensure that your wet wiper produces consistently high-quality results, minimizes waste, and operates dependably.